Welcome To

Pawaskar Engineering

Welcome To

Pawaskar Engineering

Welcome To Pawaskar Engineering

.jpg)

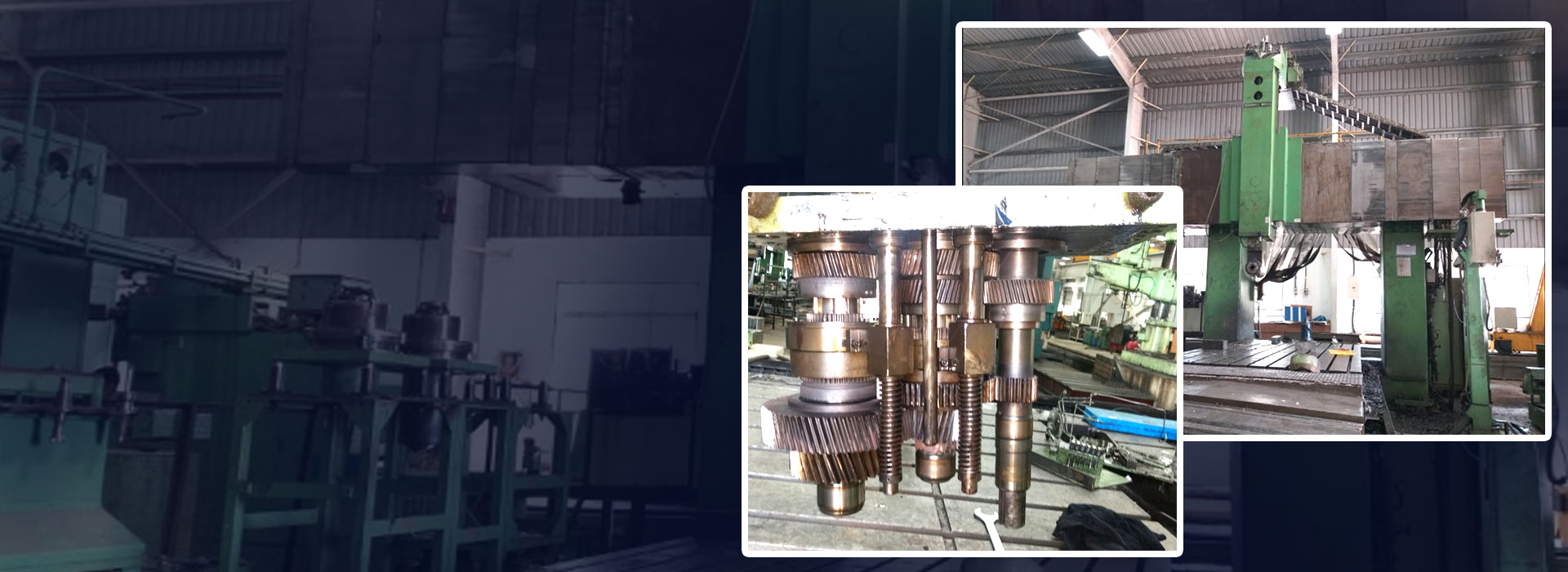

Pawaskar Engineering is a Best single source agency for Service of Machine Reconditioning, Machine Modification / Retrofitting,Machine Maintenance and Electricals Controls / Re Manufacturing. Pawaskar Engineering is Leading Provider of integrated automation systems and accessories that improve productivity enhancing comfort and ensuring customers satisfaction with safe secure and high speed automation technology. Set up in 2009, Pawaskar Engineering has developed a good demographic, in light of standards of innovation capability, legitimate dealings and faithful customer service.

Why Choose Us?

Service Guarantee

As we are equipped with expert professional’s team, we follow extreme professional while providing services.

100% Transparency & Ethical

Whichever services we offer, our experts always deliver best quality of services to our valuable customers.

Manufactured With Perfection

Our expert professional team is committed to provide all our services in time. We always deliver services on time and in effective manner.

3 Decades Of Trust

We are forever passionate about the services we provide, our work ethics and the quality we deliver to our customers.

Our Products & Services

Machine Reconditioning /Specialist in Spindle

We recondition the Machine & Spindle when they become irreparable in normal course, this is discuss with the customer at length to decide the scope and limitation.

Machine Maintenance

We Can Handle Conventional Machine in the range from Raw Material Cutting To Finish Grinding Operations.We Can Handle Mechanical Hydraulic pneumatic Coolant Systems to Repair malfunctions.

Machine Modification / Retrofitting

As per the need for customer we are able to Modify the Machines , Fixture, Tooling, Electrical and Hydraulic System to Suit customer requirement. This is Possible is if and Only if basic machine Structure allowed such Modification / Retro fitment.

Machine Shifting / Installation

Industrial Shifting or Dismantling Services are far different from any other services. It requires a Lost of time and master services supplier like Packers Industrial Shifting Services.

Design Support

During Maintenance / Modification Retro fitment some time Original Machine Catalogue. If Any Changes in Electrical/ Electronic circuit are envisaged, we have expert design services.

Electrical Controls / Re Manufacturing

The electrical control method for CNC machine tool determines the performance of the control system.